It is higly advisible to consult an experienced professional Kitchen Planner as your operation depends extremly on the smooth running of the kitchen which will reflect not only on the guest satisfaction but also on you turnover and profits.

Example: A Fully Loaded Kitchen for a 400 Seater High Class Restaurant with a Café-Bar, MICE, Breakfast, Room Service and Spa would require 30-50 Staff and would probably run 24/7.

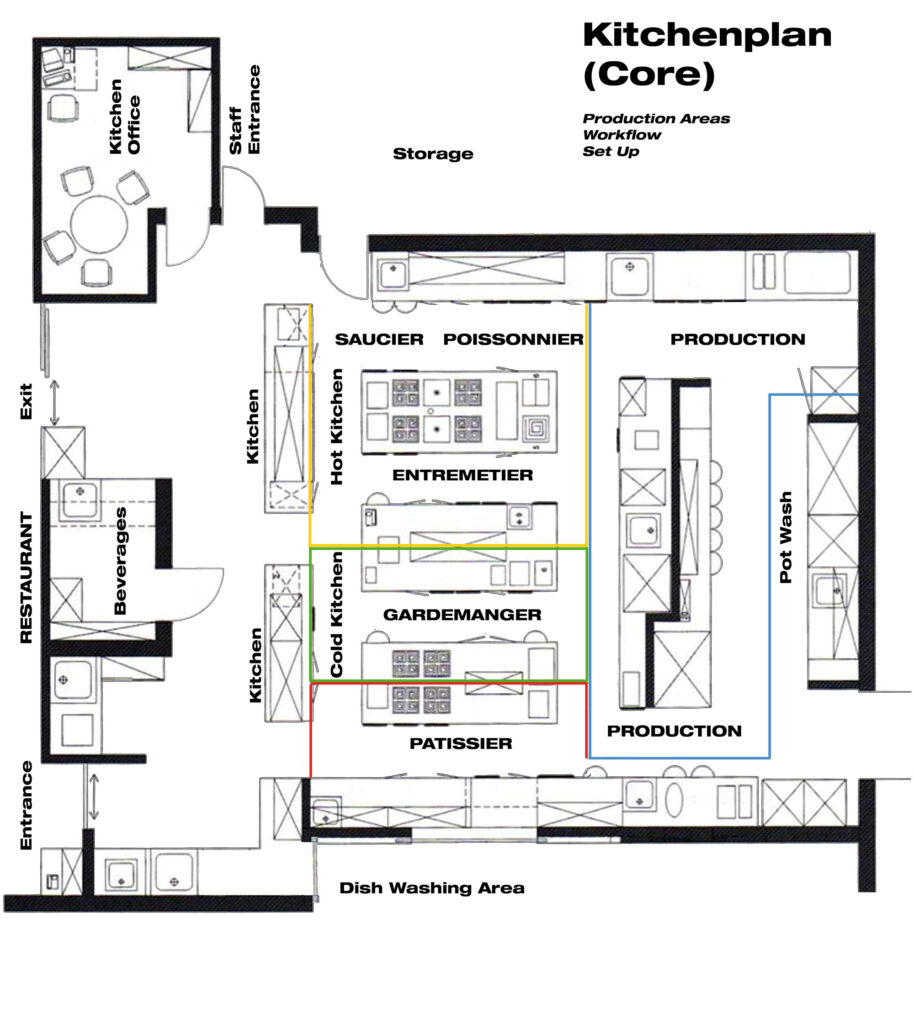

This is a plan for a fully fledged kitchen with all essential areas for a kitchen of this size and an operation as I have just specified. However – depending on the type of operation in order to plan a smooth workflow for the kitchen you need to take care of many areas and aspects.

- Kitchen office

- Purchasing

- Goods receiving

- Manipulation area for food handling

- Cold stores, fridges and freezers

- Dry storage, linen storage, china and glassware and others

- Food preparation – the impure (unrein) area of the kitchen

- Preparation and completion of the dishes – the pure (rein) area of the kitchen

- Plate set up, pass, serving

- Clearing station

- Dish washing area (scullery)

- Pot wash

- Garbage and disposal rooms

The Kitchen Set Up depends next to others on:

Type of Restaurant, Service Style, Size, Seats, Staff, Opening Hours, Level of Guests, Budget, …

And there are many types of kitchens

Preparatory kitchen, Conventional kitchen (mixed kitchen), Production kitchen, Manufacturing kitchen, Fast food kitchen, Satellite kitchens, Show kitchen, View kitchens, Kitchen for communal catering, Industrial kitchen, …

KITCHEN – FF&E for the smooth running of the kitchen

The smooth route of the goods through the kitchen, from receiving the goods to the guest, should be the logical and optimal template for kitchen planning

Kitchen Gear

- Broilers and Salamanders – a grill characterized by very high temperature overhead electric or gas heating elements

- Deep Fryer – a heated vessel for frying food by immersing in hot fat or oil, as opposed to shallow frying in a frying pan

- Tilt Skillet – a versatile restaurant appliance that holds 30 gallons and can be used to simmer, steam, braise, roast, saute, fry, boil or broil

- Other Kitchen Gear – kettles, cookers, mixers, blender, food processors, slicers, vacuum sealer, cutting boards, sinks, cooling draws, microwave, heating bridges, bain marie, Kitchen Display System

- Storage racks

- Shelving

- Safety equipment

- Freezers and refrigerators

- Food preparation counters

- Work surfaces

- Clearing stations

Next to the needed gear you need to plan the fittings

- Technical requirements and installation

- Ventilation technology

- Lighting, electricity, water supplies, drainage, exhaustion,

- Work surfaces – measurements

- Work surfaces like marble top (slab) – patisserie

As an example just the oven requires a lot of conciderations:

- Range top – Stove with 4, 6 or 8 burners a device commonly used for cookery which is commonly found in kitchens, powered by gas or electricity

- Induction Cooktop – a stove where your pan is heated by a magnetic field

- Flattop, Griddle, Grill – unlike a griddl, a flat top doesn’t have a grate. A grill has a metal framework used for cooking food over an open fire with a grid-iron

- Conventional Oven – an oven that uses radiant heat and does not use a fan to recirculate heated air

- Convection Oven – an oven that has a fan with a heating element around it

- Combi Oven- an oven with three functions: convection, steam and combination cooking.

And then there is the Kitchen Maintenance

It should come as no surprise that maintaining the restaurant’s kitchen equipment is essential to running a smooth operation. An unforeseen equipment failure can shut down an entire restaurant on a busy, Friday night. Even worse, an unexpected fire could close an establishment for several days or weeks.

The solution to preventing unexpected shutdowns and subsequent costly emergency repairs, is to organize a restaurant maintenance program.

Such a system will prioritize routine maintenance tasks, provide clear guidelines for completion, track equipment history, and hold workers accountable.

It is like changing the oil in your car, can drastically increase the life span of the equipment.

Need help? – Contact me!